Drill Heads

A number of drill head types are used for centre hole drilling. The selection of the drill head to be used for a particular application is usually governed by considerations of access during the drilling process:

Straight drill head (medium-speed electric motor): This drill head is shown below is used for most measurements with free access. The collet diameter is 7 mm (increasing to 10 mm further from the cutter), which allows a reasonably close approach to step-up features. Long series (or extended) drilling cutters can be used with this drill to allow closer approaches to higher step-up features.

Large Mechanical RA drill head (medium-speed electric motor): This was the first right-angle drill head produced by Stresscraft (~1999). It can penetrate to a depth of 200 mm at a diameter of 60 mm; the use of shortened drilling cutters and a modified clamping screw can reduce the diameter to around 50 mm.

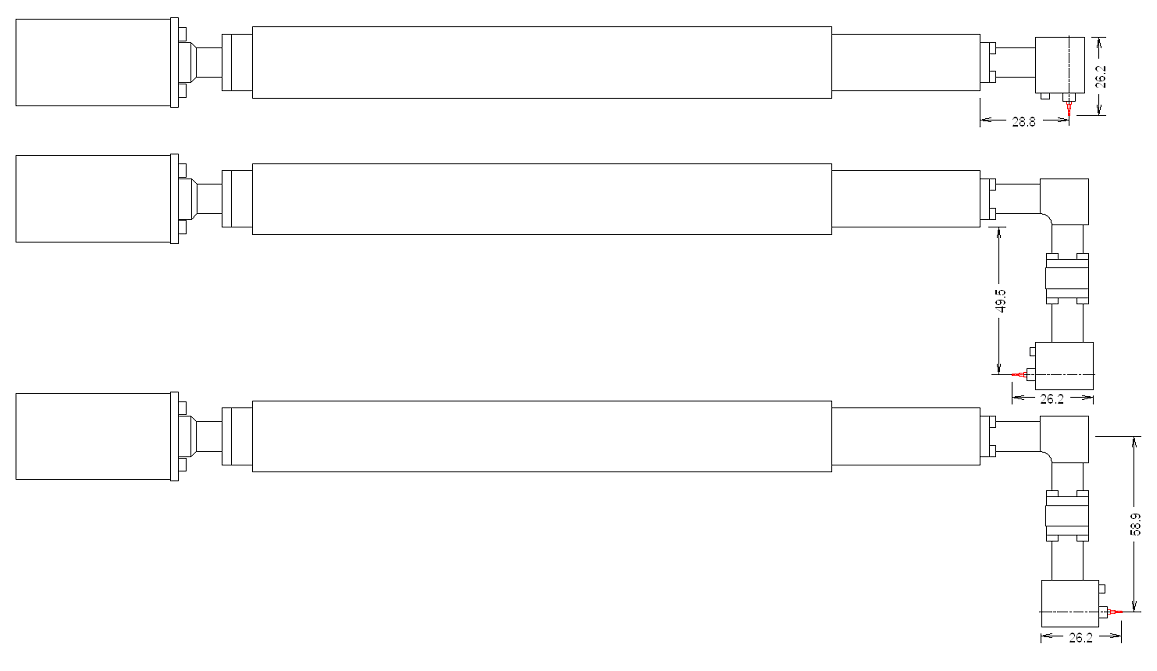

Mechanical RA drill head (medium-speed electric motor): This drill head is a development of the larger Stresscraft design, the size has been reduced in order to achieve access to smaller component details (rather than simply within disc bores). The range of applications has been increased by the addition of an optional RA adapter which provides for large offsets (49.5 mm dimension from drill holder to drilling cutter axis). For aerospace engine components, this drill head finds applications in small disc bores, on the inner sides of flanges and within F1 engine pistons, cylinder blocks and heads.

Air-turbine right-angle drill head (high-speed): This drill head is for use in places of restricted access (e.g. in smaller hub bores, inside disc drive arms, on the reverse faces of drive flanges, etc). The image shows the drill head held by a universal swivel arm; a number of other arms (straight, curved, small fixed right-angle, etc) are available to suit required applications. In addition, other adapters are available for soldering to tubes for special applications.

Miniature offset drill head (medium-speed electric motor): The offset drill head is used for drilling 031-size gauges in bolt holes and piston pin holes, under ledges, etc. The gearbox within the drill head and flexible drive from the motor provide the offset at the drill axis. The minimum recommended diameter of the target hole is around 11 to 12 mm