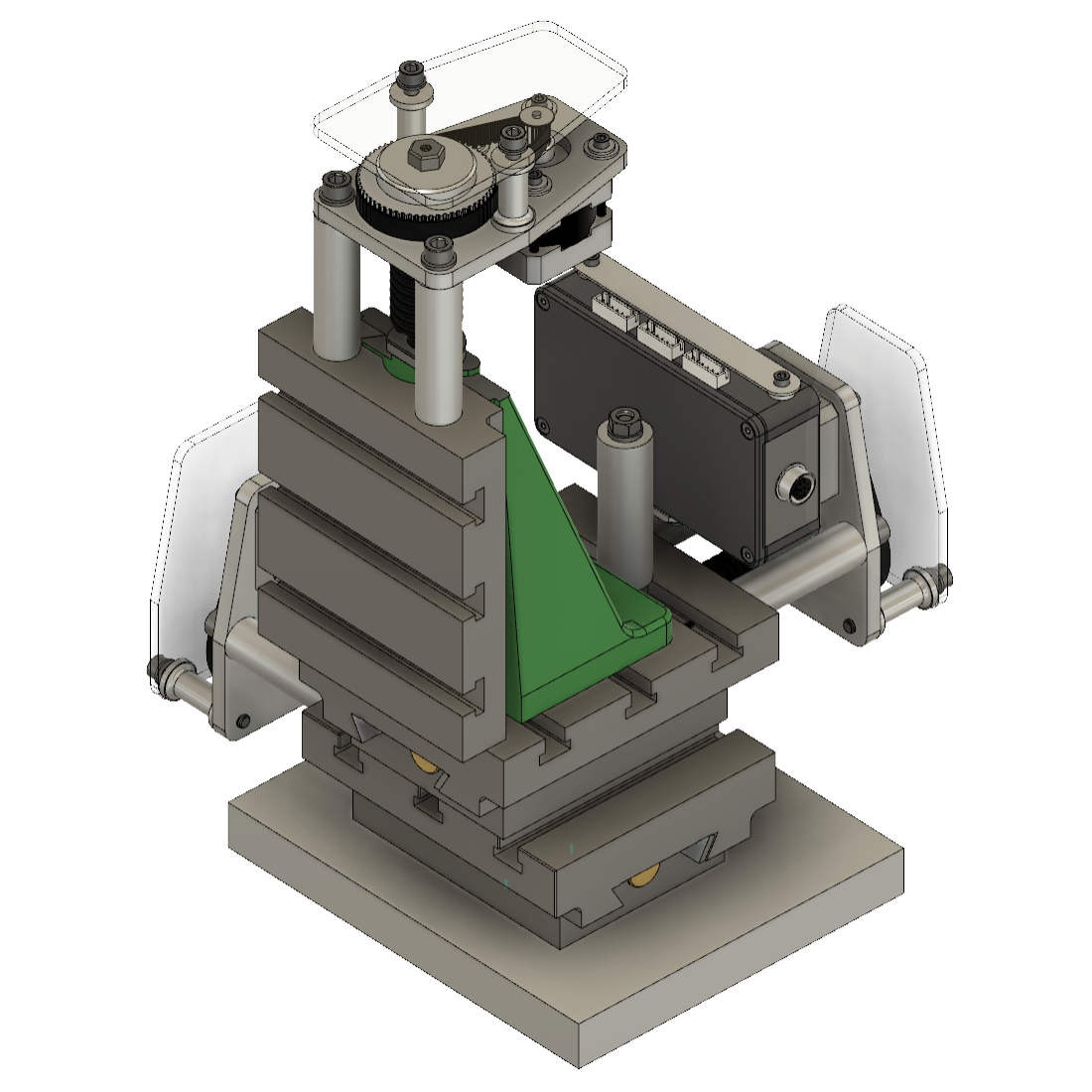

Drilling Machine

The Stresscraft Drilling Machine has been developed over a number of years to provide a means of carrying out centre hole drilling in a repeatable and reliable manner. When set up with a conventional ‘straight’ drill head, the machine is ideal for use on conventional material samples and straightforward sites. When used in conjunction with a group of specially designed drill heads, the machine provides access to hole drilling at ‘difficult’ sites in complex engineering components and structures.

Features of the machine include:

three machine slide stages (x, y and z) each controlled by a 1 mm pitch ball-screw and 200-step motor with 5:1 toothed belt drive providing a resolution of 1 micron per step.

a flanged base holding the x- and y-stages and a removable z-stage terminating in a tee-slotted bed for mounting drill heads in any configuration.

control by a PC via a DAC Input/Output card.

a machine-mounted control unit with a single removable plug for connection to 1U Power Supply and PC units.

The PC panel (shown above) includes all controls necessary for setting up, operation and (when required) strain measurement and recording. Controls include:

origin definition and reset; drill head x, y and z position control and movement,

on/off control of the drill motor (electrical, or air valve when using a turbine),

gauge size, number and depth of drilling increments, orbit eccentricity, feed rate,

drill direction vector (holes can be drilled in any selected direction), drill datum detection routine, reference points,

movements for calibration routines,

strain Indicator set up and calibration, channel control, strain recording and transfer to MS Excel.

Images below show a conventional ‘Straight’ drill head fitted to the drilling machine using an articulated mounting arm. The arm provides scope for rotation and positional offsets of the drill head for drilling in any direction.